|

|

| |

|

| |

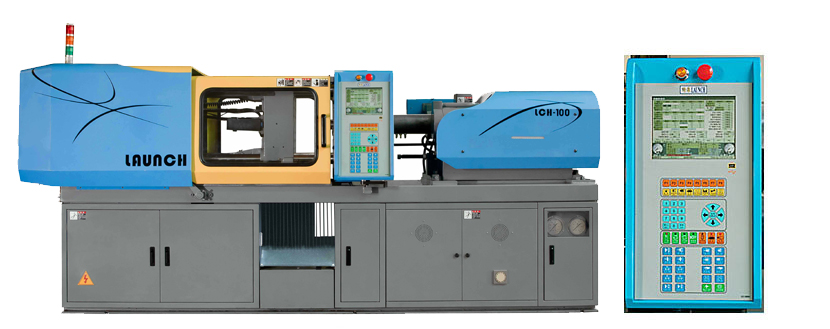

D Type Large Screen Computer |

| |

|

Click to Enlarge

Click to Enlarge |

Mold Unit Features

- Auto mold adjustment devices is according to the mold

clamping force and automatic setting mold clamping high

and low pressure and position. The mold clamping low

pressure use can automatic adjustment during production.

- Mold close/open slow speed function to protect mold

damaged during mold adjustment.

- Mold no open when bad product occur and low pressure

mold clamping again function.

- Mold unit and injection unit setting lubrication time

reach and alarm function and conformation by checker

function.

- Position confirm function for mold middle plate and

ejector plate.

- Mold close with five stage speed control function

included two stage low pressure function.

- Ejector function with counter, interval position and

interval time backward three type mode to select and

ejector forward / backward two stage pressure and speed.

- Core in have six type to select and core out seven

type to select and four type core interval position

select function.

- Air blow function have eleven type mode to select

function.

- Automatic silicon spraying function to upgrade machine

automation.

Injection Unit Features

- All in one setting page function to keep all data

complete at one page to simply setting and checking.

- One week preset time control On/Off function for Hopper

Dryer, Barrel and attachment equipment function.

- Five stage injection speed, five stage holding pressure

and multi holding exchange function (timer, position,

injection inter cylinder pressure and inter mold pressure).

- Injection shortage and material leakage checking function.

- Five type auto purge mode function to select.

- Nozzle stand forward with two speed control and backward

with three speed control function and automatic nozzle

backward function after cooling time or suck back action.

System Features

- 10.4 INCHES WITH 32 Bit color full LCD screen display.

Re-programmable data and unlimited expansion access

memory with USB function.

- Mother Board CPU use 32 Bit 66 MHZ and LCD display

32 Bit 500MHZ is equivalent with 586 CPU system, system

speed between 2MS present high speed, precise and stability

calculation.

- Three languages are available for Chinese, English

and others languages.

- More than 210 sets mold data memory can store or

load with USB function and unlimited expansion.

- Move then 100 sets revised record and 100 set alarm

record function.

- S.P.C and S.Q.C quality control with complete statistics

function and 300 sets production record page with maximum

, minimum and equalizer rate.

- After setting preset counter, the computer is automatic

calculation production counter, preview production time,

production time, production complete time, hourly production

good and bad product differentiate counter and total

machine running time record.

- Multi layer password interlock protect function to

prevent abnormal data setting.

- Product packing counter, product quality control

and conveyer delivery setting function.

- Temperature graphics and temperature P.I.D control

function, I.D rate and Pr rate adjustment function.

- Heater Temperature can set upper and lower range

point control function and temperature keep warm setting

function, thermocouple broken checking and temperature

℃ or ℉ interchange function.

- Data enter remain by maximum rate and minimum rate.

It also separated by color zone for can enter and cannot

enter display.

- When output signal is trouble we can exchange output

point to reduce machine down time.

- About 70 type of alarm output content and alarm trouble

shooting direction.

- Alarm machine breakdown have three mode to select.

- Pressure and speed display gauge and machine action

monitoring is show out on screen picture.

- Production become end to know function.

- Maintenance remaid function to keep maintenance works

simply and permanent and make sure machine at good running

condition.

- Internet connecting function to make long distance

remote detecting and data copy function (optional function).

- Picture data can store by U.S.B and use complete

copy to excel file (optional function).

Machine Features

- Mold height adjustment is control by wheel gear type

for extra rigidly and more stronger.

- Nozzle stand is support by ‘T’ shape slotted design

stand and is different with simple two tie rod type

nozzle stand design.

- Machine structure is making with all steel plate

and stronger support bar assemble for extra base stability

and extra solid structure.

- All machine parts is imported from Europe, USA, Japan

and 100% originally made in Taiwan only.

- Hydraulic pump is imported from Japan and Europe

to warranty quality and low noise presentation.

|

|

|